Custom CNC Machining Service

Quick Quotes Start Here. Sample handling and bulk goods can be completed in as fast as 3 days.

Our CNC service include: Functional prototypes. jigs and Fixtures. production components in lower volumes and Mass production.

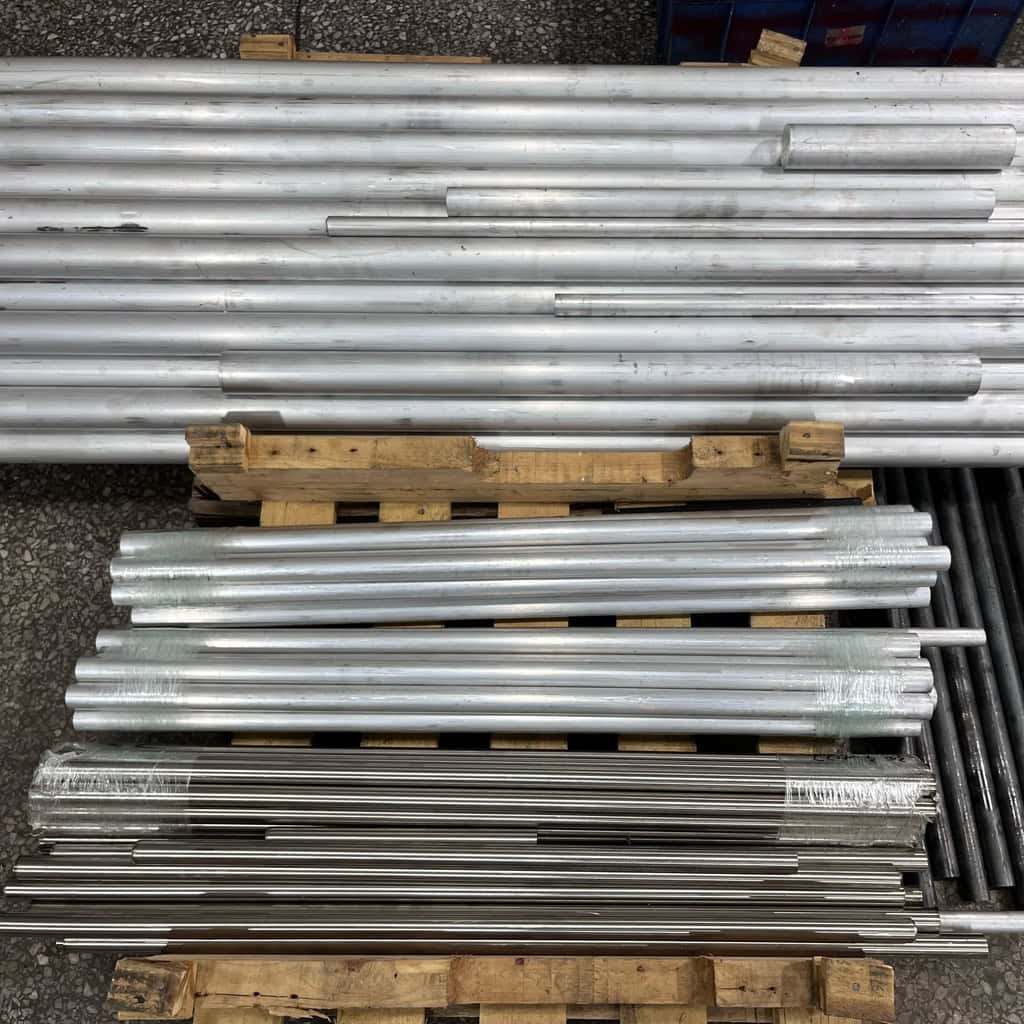

Materials Available for CNC Machining at TechTuneCNC.

At Tech Tune CNC, we offer a wide range of materials to meet the diverse needs of your projects. Below is a comprehensive list of the materials available for CNC machining, ensuring U have the flexibility to choose the best option for your application and that are suitable for various part applications and industries.

Metal:

Aluminum

- Common Grades: 6061, 7075, 5052, 2024

- Applications: Aerospace, automotive, consumer electronics

- Benefits: Lightweight, corrosion-resistant, excellent machinability

Steel

- Common Grades: 1018, 1045, 4140, A36, Stainless Steel (304, 316)

- Applications: Structural components, automotive parts, industrial machinery

- Benefits: High strength, durability, excellent wear resistance

Brass

- Common Grades: C360, C385

- Applications: Plumbing, electrical components, decorative fittings

- Benefits: Good machinability, corrosion resistance, aesthetic appeal

Copper

- Common Grades: C101, C110

- Applications: Electrical connectors, heat exchangers, plumbing

- Benefits: Excellent electrical and thermal conductivity

Titanium

- Common Grades: Grade 2, Grade 5 (Ti-6Al-4V)

- Applications: Aerospace, medical implants, high-performance components

- Benefits: High strength-to-weight ratio, corrosion resistance, biocompatibility

Magnesium

- Common Grades: AZ31B, AZ91D

- Applications: Aerospace, automotive, lightweight structures

- Benefits: Extremely lightweight, good machinability

Bronze

- Common Grades: C932, C954

- Applications: Bearings, bushings, gears

- Benefits: Excellent wear resistance, low friction

Plastics:

1.ABS (Acrylonitrile Butadiene Styrene)

Applications: Prototyping, enclosures, automotive parts

Benefits: Impact-resistant, easy to machine, cost-effective

2. Polycarbonate (PC)

Applications: Transparent components, impact-resistant parts

Benefits: High impact resistance, optical clarity

3.Nylon (Polyamide)

Applications: Gears, bearings, wear-resistant parts

Benefits: High strength, wear resistance, good chemical resistance

4.POM (Polyoxymethylene) / Delrin

Applications: Precision parts, gears, bearings

Benefits: Low friction, high stiffness, good dimensional stability

5.PTFE (Polytetrafluoroethylene) / Teflon

Applications: Seals, gaskets, insulators

Benefits: High chemical resistance, low friction, high-temperature tolerance

6. PEEK (Polyether Ether Ketone)

Applications: High-performance components, aerospace, medical devices

Benefits: Excellent mechanical properties, chemical resistance, high temperature tolerance.

7.HDPE (High Density Polyethylene)

Applications: Containers, piping, marine applications

Benefits: Impact resistance, chemical resistance, lightweight

8. PVC (Polyvinyl Chloride)

Applications: Plumbing, chemical handling, electrical insulators

Benefits: High chemical resistance, easy to machine, cost-effective

9.Acrylic (PMMA)

Applications: Display cases, optical lenses, light covers

Benefits: Optical clarity, weather resistance, easy to machine

10. Polypropylene (PP)

Applications: Chemical tanks, automotive parts, packaging

Benefits: Chemical resistance, lightweight, fatigue resistance

Composites:

Carbon Fiber Reinforced Polymer (CFRP)

Applications: Aerospace, automotive, sports equipment

Benefits: High strength-to-weight ratio, stiffness, excellent fatigue resistance

Glass-Filled Nylon

Applications: Structural components, gears, automotive parts

Benefits: Increased stiffness, strength, wear resistance

G10/FR4 (Glass Epoxy)

Applications: Electrical insulators, circuit boards, structural components

Benefits: High strength, electrical insulation, chemical resistance

Selecting the Right Material.

Choosing the right material is crucial for the success of your project. Factors to consider include:

- Mechanical Properties: Strength, hardness, and flexibility

- Machinability: Ease of machining, tool wear, and surface finish

- Thermal Properties: Heat resistance, thermal expansion

- Corrosion Resistance: Resistance to environmental factors

- Electrical Properties: Conductivity or insulation requirements

- Cost: Material cost and availability

At Tech Tune CNC, our experts are here to help you select the most suitable material for your specific application, ensuring that your parts meet all required performance criteria. Let’s make sure your next project is engineered for success from the ground up!

Design Guidelines

Our basic guidelines for CNC milling include important design considerations to help improve Part manufacturability, enhance cosmetic appearance, and reduce overall production time.

3-axis. 4-axis.

559mm x 356mm x 95.3mm

5-axis.

254mm x 178mm 95.3mm

Size

6.35mm x 6.35mm

Nominal Thickness

1.02mm

Typically, Techtune can hold a machining tolerance of +/- 0.005 in. (0.13mm). Part features are recommended to be thicker than 0.020 in. (0.51mm) in all regions and a nominal part thickness above 0.040 in.

- Plastic and soft metals: Minimum width of 0.018 in. (0.457mm), depth of 0.0118 in. (0.3mm). Example text size would be 16 point Arial Rounded MT font.

- Hard metals: Minimum width of 0.033 in. (0.838mm) and depth of 0.0118 in. (0.3mm). Example text size would be 22 point Arial Rounded MT font.

- If design permits it, option for recessed text versus raised.