Custom CNC Machining Service

Quick Quotes Start Here. Sample handling and bulk goods can be completed in as fast as 3 days.

The primary processes involved in our CNC machining

Design and Programming

In this primary design and programming process. Because of our years of production and experience, we can sensitively and quickly find out whether there are any design problems in the drawings you come.

We must make sure solve the problem in the tooth eruption stage to ensure that our later production goes smoothly and the customer’s project can be completed perfectly, thereby achieving a win-win effect.

Details:

- Checking draws: When we find problems in the draws, we must solve them quickly and accurately. Propose the most effective solution for customers.

- Drawing mechanical drawings:

- CAM Software: Translates the CAD model into a series of tool paths that the CNC machine will follow.

- G-Code Generation: G-code contains instructions for tool movement, speed, feed rate, and other machine parameters.

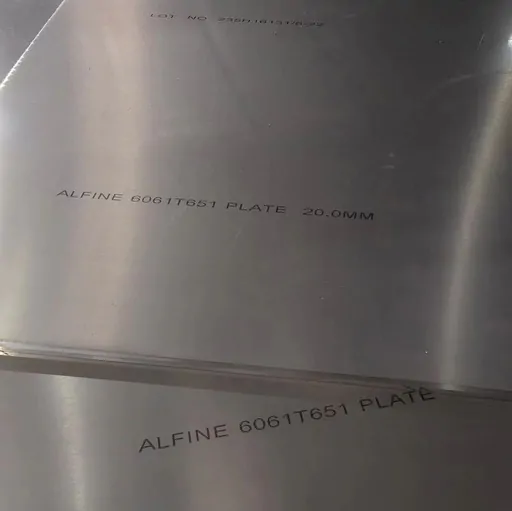

Material Selection and Preparation

After the Design and Programming, we need to prepare the Material. At this stage, we must purchase materials strictly according to the customer’s requirements. We can also choose more suitable materials for you. The appropriate material is selected based on the specifications of the part, such as mechanical properties, thermal resistance, and machinability.

- Material Selection: Metals (e.g., aluminum, steel), plastics (e.g., ABS, POM), and composites are common materials.

- Raw Material Preparation: Materials may be cut from larger sheets, bars, or blocks into manageable sizes for the CNC machine.

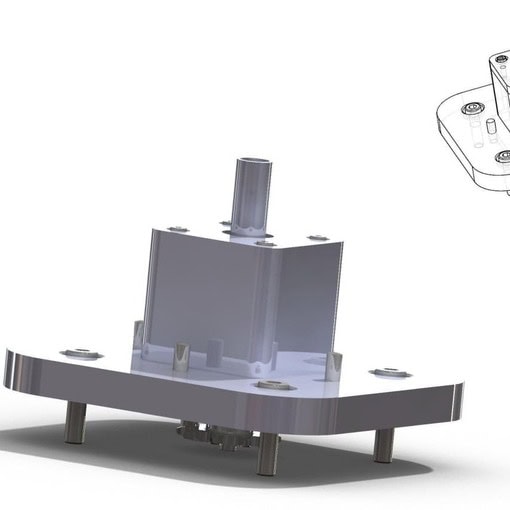

Machine Setup

The CNC machine is set up according to the specific job requirements. This includes installing the correct tools, setting up the workpiece, and configuring the machine parameters.

In this process, we must strictly implement it to ensure that customers’ products are finished with high quality.

- Tooling: Selecting and installing the appropriate cutting tools (e.g., end mills, drills, lathes) for the job.

- Workpiece Setup: The workpiece is securely clamped or fixtured onto the machine table.

- Calibration: Ensuring that the machine is properly calibrated, including setting the origin point (zero point) and verifying tool offsets.

Machining Operations

This is the core of CNC machining, where the machine cuts, drills, mills, or grinds the material to form the desired part. Multiple operations may be required depending on the complexity of the part.

Details:

- Milling: The cutting tool rotates to remove material from the workpiece, producing flat surfaces, slots, and complex geometries.

- Turning: Used for cylindrical parts, where the workpiece rotates while the cutting tool moves linearly.

- Drilling: Creating holes in the workpiece using a rotating drill bit.

- Grinding: Finishing process for achieving tight tolerances and smooth surface finishes.

Inspection and Quality Control

After machining, the part undergoes a rigorous inspection process to ensure it meets the required specifications and tolerances.

Details:

- In-process Inspection: Measurements and checks are made during machining to catch any deviations early.

- Final Inspection: The finished part is measured using precision instruments like calipers, micrometers, and coordinate measuring machines (CMMs).

- Quality Control: Inspectors check for dimensional accuracy, surface finish, and any defects.

Post-Processing

- Depending on the part’s requirements, additional finishing processes may be applied after machining to enhance the appearance, functionality, or durability.

Details:

- Deburring: Removing sharp edges or burrs created during machining.

- Surface Treatment: Applying coatings, anodizing, or polishing to improve surface quality and corrosion resistance.

- Heat Treatment: Strengthening the material through processes like annealing, quenching, or tempering.

- fdm 3D printing.

Assembly (If Needed)

- For parts that are part of a larger assembly, the CNC machined components may need to be assembled with other parts.

Details:

- Fitting: Ensuring that all parts fit together correctly.

- Joining: Techniques like welding, screwing, or gluing may be used to assemble components.

- Testing: The assembled part may undergo functional testing to ensure it operates as intended.

Packaging and Shipping

Once the parts are fully processed and inspected, they are carefully packaged and prepared for shipment to the customer.

Details:

- Packaging: Parts are protected using appropriate packaging materials to prevent damage during transit.

- Labeling: Proper labeling with part numbers, batch numbers, and destination details.

- Shipping: Arranging logistics to ensure timely and safe delivery to the customer.

Consultation: Understanding Your Unique Needs

We begin by listening to your vision and requirements, gaining a deep understanding of your unique needs.

Design and Prototyping: Precision from the Start

Experience precision from the very beginning with our meticulous design and prototyping process.

Production and Delivery: Turning Concepts into Reality

Watch as we bring your concepts to life with efficient production and timely delivery.

Customer Testimonials

Experience Unmatched Precision and Quality with TechTune CNC's Services, Solved a lot of my problems.

At TechTune CNC, we offer a range of services that provide improved efficiency, cost savings, and superior quality. Our team of experts is dedicated to delivering customized solutions that meet your exact specifications.

Boost your manufacturing operations with efficient and reliable services.

Experience the TechTune CNC difference for yourself today.

TechTune CNC has exceeded our expectations in delivering high-quality CNC parts that perfectly match our specifications. Their commitment to punctual deliveries and competitive pricing has made them our trusted partner in manufacturing excellence.

John Doe CTO, ABC Manufacturing

Webflow

FAQs

Find answers to common questions about our services, turnaround times, material capabilities, and order processes.

What services do you provide?

TechTuneCNC provides a variety of services primarily focused on CNC (Computer Numerical Control) machining and related technologies. While specific offerings may vary, typical services provided by companies in this field often include:

- CNC Machining Services: Precision machining of parts using CNC technology, including milling, turning, and routing.

- Custom Part Manufacturing: Fabrication of custom components based on client specifications and designs.

- Prototyping: Creating prototypes for product development to test form, fit, and function before mass production.

- Design Services: Assistance with product design or modifications to existing designs for manufacturability.

- 3D Printing Services: Additive manufacturing capabilities to create parts quickly and efficiently from various materials.

- CAD/CAM Programming: Software solutions to convert CAD designs into machine-readable instructions for CNC equipment.

- Consulting Services: Expert advice on optimizing manufacturing processes or implementing new technology in production lines.

- Tooling Supply & Production: Providing tools necessary for CNC operations or creating custom tooling solutions.

- Maintenance & Repair Services: Offering maintenance packages or repair services for CNC machinery to ensure optimal operation.

For the most accurate information regarding TechTuneCNC’s specific services, it is best to visit our official website or contact us directly.

What is your turnaround time?

About TechTuneCNC’s turnaround time for their services. Turnaround times can vary based on several factors, including the complexity of the project, the type of service requested, current workload, and material availability.

- For mini order, about 1 to 10 samples the leadtime is about 1 week.

- For bulk productions the leadtime is about 10 days to 1 month, it is base on the volumeof the order.

For accurate information regarding the turnaround times for specific services or projects, it’s best to consult us directly through our official website or contact us via phone or email. We would provide the most up-to-date and relevant information based on your needs.

What materials do you work with?

TechTuneCNC typically works with a variety of materials. materials include:

- Metals:

- Aluminum

- Steel (various grades)

- Stainless steel

- Brass

- Copper

- Plastics:

- Acrylic (PMMA)

- Polycarbonate (PC)

- Nylon

- Delrin (Acetal)

- PVC

- Composites:

- Carbon fiber

- Fiberglass

- Wood:

- Various types of hardwood and softwood.

- Foams and Other Materials: Depending on the specific services offered, Wealso work with different foams or specialized composite materials.

For the most accurate and detailed information regarding their capabilities and material options, it’s best to contact us directly.

What is your order process?

TechTuneCNC’s order process follows these steps:

- Inquiry: Customers reach out to inquire about services, provide project specifications, and ask any preliminary questions.

- Quote Request: Customers submit a request for a quote (RFQ) by providing detailed information such as drawings, material specifications, quantities, and any other relevant details.

- Initial Consultation: This may involve discussing the project in more depth to clarify requirements and expectations.

- Quotation Provided: Wewill send a formal quote that includes pricing, lead times, and any necessary terms of service.

- Order Confirmation: If the customer agrees to the quotation, they will confirm the order either via email . Payment terms might be discussed here as well.

- Design Verification: In many cases, customers may need to approve final designs before production begins—this could involve sending CAD files for review.

- Production: Once everything is confirmed and approved, the manufacturing process begins based on agreed timelines.

- Quality Control: The produced parts will undergo quality checks to ensure they meet specified tolerances and standards.

Can I request a quote?

Yes, you can typically request a quote from TechTuneCNC. To do so, you would generally need to provide specific details about your project, including:

- Project Specifications: Include any drawings or CAD files that outline the design and dimensions of the parts you need.

- Material Requirements: Specify the type of material you want used for your CNC machining project.

- Quantity: Indicate how many units you require.

- Timeline: Mention any deadlines or expected lead times.

To initiate the quote request, visit our official website and look for a “Get a Quick Quote” section or contact our sales team directly via email or phone. We will guide you through our specific process and provide an accurate quote based on your requirements.